Product customization and pre-fabrication services is a time and labor-saving investment for Distributors and Contractors that have taken advantage of this service from EPCO. Why? Because our customization and prefabrication service are built exactly to Distributor and Contractor specifications to meet their application requirements.

GOOD PROJECT PLANNING

Prefabrication involves identifying repeated field installation tasks that can be constructed ahead of time. It’s a versatile construction method that allows greater flexibility than traditional construction methods. More importantly, prefabrication is the result of good project planning. And the Electrical Project Manager on any job site is always looking for better and innovative approaches to expand efficiency, speed up installations, and increase capacity for their electricians.

We (EPCO) can provide a complete, prefabricated solution that provides time and labor savings, eliminating the need to wait for the right components to be assembled on the job site. Our prefabricated solutions range from simple, basic assemblies to more complex assemblies.

In addition, we simplify the complexities of materials management to suit the Project Manager’s application needs. We work with the Distributor and Contractor to develop and finalize project planning from design conception through installation.

Depending on the project, we provide the “right” prefabricated assemblies to eliminate any “running around” to get the needed components to the job site. We add value to the project with the underlining goal of providing:

- Accelerated Installations

- Lower Job Site Labor Costs

- Fixed Pricing

- Saving Time and Increase Job Site Capacity

- Eliminate Material Storage and Waste

TYPICAL APPLICATIONS

Our prefabricated capabilities are suitable for a broad variety of job site applications and installations including:

- Hotels and Motels

- Office Buildings

- Commercial Strip Malls

- Single Homes, Multi-Family Dwellings, Condominium Buildings and Towers

- Transportation Facilities

- Medical and Health Care Facilities

- Warehouse Spaces, and More…

EPCO’s overview of our prefabrication strategy highlights cost savings, time savings, and job site advantages:

COST SAVINGS

- Bulk Cost Savings — Standardize cost across projects and save money by special bulk pricing.

- Reduced Waste — Cost savings through “green” building goals (one of the primary motivations behind prefabrication).

- Lower Labor Costs — Prefabricated assemblies ahead of field installation reduce labor costs, minimizes installation errors and rework.

- Improve Safety — When considering complex electrical installations, installing something prefabricated is faster and safer.

- Reduce Estimating Costs — Prefabricated assemblies can be added to your system to expedite your costing process.

TIME SAVINGS

- Prefabrication can begin before construction is started.

- Project timeline for completion is reduced and not impacted by other events on the job site.

- Streamlines and speeds-up installation, resulting in less overtime on the job site.

- Built to exact job site specifications saving time on ancillary issues, like missing or forgotten materials or tools.

- Eliminates material handling and waste; everything is in place and ready for installation.

JOB SITE ADVANTAGES

- Prefabricated assemblies are built to exact specifications.

- Increases and Improves job site productivity and labor savings.

- Installation efficiency, eliminates overtime costs.

- Negates effect of weather; prefabricated assemblies are manufactured in a controlled environment providing a higher quality result.

WHAT CAN EPCO PREFRABRICATE?

Virtually any type of wire related assemblies or components that will be consumed and installed on the job site. We recommend the following product products to support basic prefabricated solutions:

- Ground Bonding PigTailsTM and PowerTails® Device Wiring Conductors. This includes pre-assembling the receptacles and switches at the electrical contractor’s workshop – for quick and simple installation and termination on the job site.

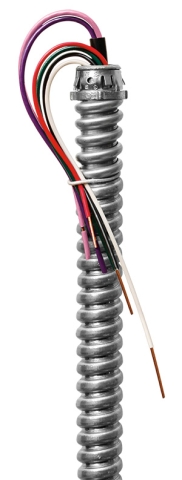

- Prefabricated Fixture Whips - Over 300+ configurations immediately available that can be manufactured in a cost efficient and effective manner in any length, wire gauge size, with your choice of steel or liquid tight conduit.

- Other Custom prefabricated capabilities are readily available to meet your application requirements.

For more specific information contact your EPCO Sales Rep, Regional Sales Manager or EPCO Inside Sales at sales@engproducts.com or 800.336.1976