by Allen Guidry, III Marketing Manager

So I received a call from a contractor that just opened a lighting retrofit business. He was retrofitting an old warehouse and the lighting system was strip-type light fixtures using old T12 fluorescent lamps. He told me the building owner was on a very tight budget and wanted to get the best sustainable lighting at the lowest possible cost. In addition, he did not want to install new LED luminaires — instead, he wanted to re-purpose the existing light fixtures and convert them to use LED lamps.

After visiting Engineered Products Company's (EPCO) website, the contractor found what he needed for the job our Fixture Bracket RetroFit Conversion Kits, specifically designed to convert old “ballast driven” T12 and T8 fluorescent fixtures to light fixtures using LED lamps with built-in LED Drivers.

At EPCO, we are always aware of changing lighting technologies in the marketplace — what is new, cool, sustainable, and what saves money. I reinforced what the contractor read on our website and clarified his search with a quick verbal overview - so it was time for some schooling primarily on the benefits of using EPCO’s Fixture Bracket Kits and why:

- Retrofitting takes half the time and half the cost compared to installing a new lighting system.

- Installation is expedited by 25%!

- Fast and simple upgrade to energy efficient lighting.

- Initial energy savings up to 40% or more.

- Payback periods from 15 months to 3 years for most installations.

- Sustainable ongoing energy savings.

- The original fixture housing is reused.

- Minimal rewiring and recycling on the job site.

Fixture Bracket RetroFit Conversion Kits - And Why

When retrofitting strip-type light fixtures using old T12 or T8 fluorescent lamps, EPCO offers two types of Fixture Bracket Kits, the 140xx Series for Single-End Powered LED Lamps (4-foot and 8-foot lengths) and the 180xx Series for Double-End Powered LED Lamps (4-foot and 8-foot lengths).

The Actual Lamp Differences

Obviously, LED lamps have two ends and four pins (two pins on each end) to hold it in place regardless of installation, type, or length. When an LED lamp is “single-end powered”, this means the LED lamp is powered from one end only. But, when electricity is wired to power the LED lamp from both ends, this is a “double-end powered” lamp. Pretty straightforward, right?

What Type of LED Lamp Should the Contractor Use?

Single-end powered LED lamps do not use a ballast, but instead have an LED driver built into the lamp. This LED lamp type does not require the installation of non-shunted tombstones on one side of the lamp because the hot and neutral are on the same side of the lamp.

Old T12 fluorescent lamps are double-end powered, meaning one end of the electrical feed is hot and the other side neutral. The lamp holder (or tombstone) is “shunted”, meaning two contacts on one side of the lamp are shorted together with no voltage difference between them.

Double-end powered LED lamps are energized exactly the same as fluorescent lamps: the live and neutral pins on the opposite end of the lamp. And the double-end powered LED lamp can be used with shunted or non-shunted lamp holders.

So now the contractor is going to replace the old T12 fluorescent lamps with T8 LED lamps knowing this lamp type will deliver an improved and sustainable lighting solution resulting in less up-front installation work because he can re-use the existing sockets without rewiring the light fixture. But wait!

Call Backs Cost Money

Because of always present UV rays and the underlying age of the strip light fixture, old fluorescent sockets often need to be replaced beyond the two reasons I've stated. The majority of contractors I’ve historically spoken with over the years do not want to return to the job site a few weeks later because they actually lose any margin gains on call backs.

My recommendation to this contractor is to go for a more complete retrofit and lighting upgrade by using either of EPCO’s 140xx or 180xx Series Fixture Bracket Kits for the most important reason — elimination of the dreaded call back, rework, and loss of his profit margin.

The Real Consideration: Installation Time

EPCO’s low-cost Fixture Bracket RetroFit Conversion Kits take into account budget, operating environment, required lumen output, energy saving goals, and minimum efficacy requirements for utility rebates, to deliver the optimal lighting system solution.

Did I mention the building owner had already purchased double-end powered T8 LED lamps? And the cost between the double-end powered vs. single-end powered lamps is about a $3.00 difference.

The electrical lighting market is trending toward the application use of double-end powered T8 LED Lamps. This lamp has a high brightness output at 2,200 lumens each, making it an ideal lamp to brighten the old warehouse while adding sustainability over 45,000+ hours (or 5.13 years’ operating at 24/7 all year), a common characteristic for double-ended powered LED lamps.

For dual-end powered T8 LED Lamps, our 180xx Series Fixture Bracket Kits are available in two configurations:

- Standard Fixture Bracket Kits (4-foot and 8-foot lengths). Installation time - 25 to 30 minutes.

- Pre-wired Fixture Bracket Kits (4-foot and 8-foot lengths including supply line conductors and luminaire disconnect). Installation time - 10 to 15 minutes.

Note: Strip-type light fixture length factors into the installation time.

And the new lamp holders are integral to our retrofit kit, so everything is “new” a plug and play installation to eliminate (virtually) any call-backs.

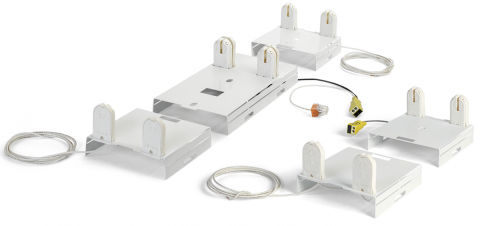

The image below provides an overview of EPCO’s double-end and single-end powered pre-wired Fixture Bracket RetroFit Conversion Kits (and these kits include new lamp holders).

So either the Fixture Bracket RetroFit Conversion Kits for single-end or double-end powered lamps can support the contractor’s application requirement.