Description

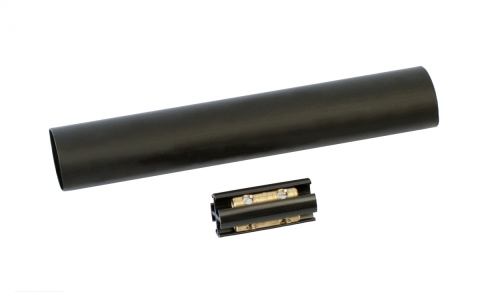

Thick Wall Heat Shrink Tubing (HST) is used to dielectrically insulate and encapsulate electrical connections. The HST internal coating has an adhesive and sealant that melts when the tubing is heated to provide a moisture and soil resistant seal. The standard color is black.

- UL Listed for direct burial. File #E123896.

- Meets the requirements of the 2023 National Electrical Code: Articles 110.14(B), and 300.5(C)(E).

- Installs and shrinks easily for labor savings. Most effective when insulating over large transitions.

- 3:1 Shrink ratios enables wider cable range and fewer tubing sizes.

- Excellent abrasion, corrosion and environmental resistance properties.

- UV and fungi resistant.

Part Numbers

Product Spec

| PROPERTY | TYPICAL PERFORMANCE |

|---|---|

| PHYSICAL | |

| Tensile Strength | 2100 psi (14.5 MPa) |

| Specific Gravity | 1.1 |

| Heat Shock (4 hrs at 437°F (225°C) | No cracking and flowing |

| Low Temperature Flexibility (4 hrs at -67°F (-55°C) | No cracking |

| ELECTRICAL | |

| Dielectric Strength | 500 V/Mil (20k V/mm) |

| Dielectric Voltage Withstand (2500V, 60Hz, 1 min) | No breakdown, 24kV - 1 min 15kV - 4 hrs |

| Volume Resistivity | 1016 ohm-cm |

| CHEMICAL | |

| Fluid Resistance | Good to excellent |

| Cooper Corrosion | No corrosion |

| Water Absorption | 0.1% |

| Fungus Resistance | No growth |

| ADHESIVE | |

| Adhesive Softening Point | 197°F (92°C) +/- 41°F (-5°C) |

| Adhesive Lap Shear | 125 psi (0.875 mPa) |

| Adhesive Blocking (86°F (30°C)) | No blocking |

| Water Penetration | No penetration after 236 hrs (min) of continuous immersion |

Dimensions

Refer to the table shown below to select the Heat Shrink Tubing size which will shrink to fit snugly over the component to be covered. If recovery is restricted the resulting wall thickness will be less than specified.